Making it Stable: Rebalancing a CNC Table

The CNC machine at Crafter's Lab wasn't performing as precisely as it should have been. I quickly deduced that the constant moving of the table was throwing it out of balance. As a designer, I see a problem like this as a challenge: how can I make the table stable, even when it's being moved? My solution was to re-engineer the legs with adjustable feet.

The Problem with Hinges and Old Designs

The table's original design had hinged feet, which was a smart idea for making it foldable. However, years of folding and unfolding had worn down the hinges, making the entire table shaky. The table was also leveled on a different floor, so the legs were uneven, leaving the table permanently slanted.

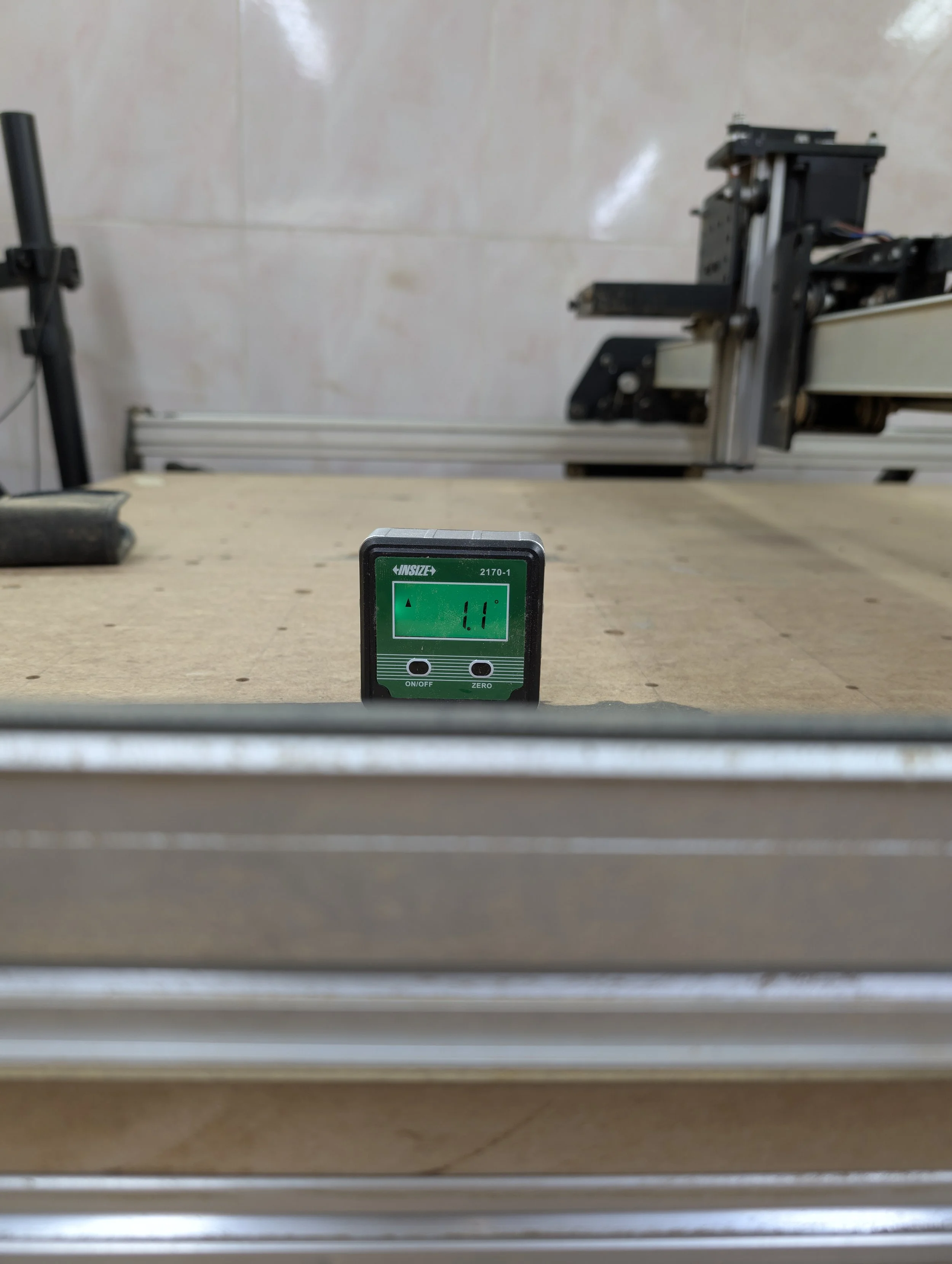

To fix this, I made the call to sacrifice the folding feature. I drilled holes in the bottom of each leg for an adjustable leveling foot and dead-screwed it in place. By getting rid of the worn-out hinges, I eliminated the source of the shakiness, making the table stable and reliable once again.

The Challenge of Primitive Tools

The biggest challenge in this project was not the design itself, but the execution. I needed to saw away a bit of the bottom of the legs to fit the adjustable feet. With no access to a proper saw, I had to use a handsaw for the job. It took a while, but it was a great lesson in making the most of the tools you have. I also learned to cut a bit more than I needed to accommodate for the thickness of the foot and to account for any future dipping.

This project was a great reminder that sometimes, the best solution isn't a new design but a more reliable one. By removing an unstable, obsolete part of the table, I made it more stable and precise, which was the ultimate goal.